What Can We Help You With?

Emergency Concerns: Our website is not monitored 24 hours a day or on weekends. Incidents of an emergent nature (medical, suspicious or criminal activity, highway emergencies, etc.) should be reported by dialing 911 or your local law enforcement agency.

Request Public Records

Connect With Us

Know the person you want to contact? Find their information on the State Employee Directory.

Interested in employment opportunities? Visit our Careers page for information.

District Contacts

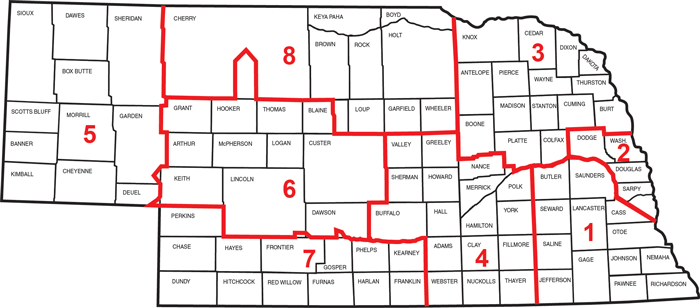

District 1

Brandon Varilek | Lincoln | 402.471.0850

District 2

Thomas Goodbarn | Omaha | 402.595.2534

District 3

Kevin Domogalla | Norfolk | 402.370.3470

District 4

Wesley Wahlgren | Grand Island | 308.385.6265

District 5

Doug Hoevet | Gering | 308.436.6587

District 6

Gary Thayer | North Platte | 308.535.8031

District 7

Kurt Vosburg | McCook | 308.345.8490

District 8

Mark Kovar | Ainsworth | 402.387.2471

There are several ways to find information within the Nebraska Department of Transportation website. The first of these is to use the five tiles on the front page. These sections are Travel, Business Center, Projects, News & Media, and Safety. By hovering over each tile, you can read a brief description on the type of information that can be found within that section.

A second option on how to navigate the website is to use the search function. In the top, right-hand corner of every page you will have an option to search the website for the content you are looking for. Once you click “ Go! ” you will be taken to a new page full of search results. Choose the option that best suits what you are searching for.

A third option is to use the Transportation Links in the footer. By clicking on any of these, you will find information from both NDOT and outside resources pertaining to each mode of transportation.

The Nebraska Department of Transportation utilizes a subscription service called GovDelivery. To sign up to receive updates when a page or pages are updates, scroll to the “Resources” in the footer of the website, at the very bottom of the page. Here you can click “Subscribe to Updates via GovDelivery.” Once clicked, you will be asked to submit your email or phone number in order to receive notifications, as well as choose which page(s) you would like to subscribe to.

How does GovDelivery work?

GovDelivery® is a web-based email subscription management system that allows you to subscribe to news and information updates on the NDOT website. Whenever information is updated on an NDOT web page you have subscribed to, you will receive an email and/or mobile alert. You may customize and manage your subscription profile in order to receive exactly the types of information you desire, and you may cancel your subscriptions at any time.

Will it cost me anything to subscribe?

No. The subscription service is offered as a public service from the State of Nebraska and NDOT. The only costs that may apply are for text messages sent to your mobile device, based on your cell phone plan.

What is a profile, and why do I need to create one?

A profile contains your email address, an optional password, and the selections for which you wish to receive email updates. You can also add a secondary email if you wish to receive notifications to another account. Your profile tells NDOT which email updates you wish to receive. NDOT is also asking for your City, County, State & Zip. That would be used only if we need to send an Special Alert to a specific area within Nebraska. We could define the area by that information. You can change your profile at any time by adding or deleting subscriptions, changing the frequency of email notifications, or changing your email address.

How will I receive the updates?

An update will be delivered to your inbox or mobile phone when the information that you have subscribed to has been updated on the web page. Remember, mobile info may incur a charge set by your carrier. Emails are free.

I subscribed to receive email alerts, but I haven’t gotten any yet. Why not?

You should receive a “New Subscriber” email as soon as you subscribe for each item you select. To ensure that you receive your subscription emails, you may need to adjust your Spam settings, or follow the instructions from your email provider on how to prevent our emails from being marked "Spam" or "Junk Mail." If you received the “New Subscriber” email, but have not received anything further, the item(s) you selected may not have been updated recently, and there has been no need to notify you.

For questions about the Public Records Act, please refer to the Nebraska Attorney General’s website.

Watch a video, "From Concept to Construction," to learn the process of a highway project.

To learn how your business can survive and thrive through roadway reconstruction, download this brochure or watch this video (also available below).

Learn how speed limits are established in our Speed Limit Brochure.

NOTE: Rumble strips are used on the sides of highways in Nebraska and across the United States as a safety measure to alert drivers when they are near the edge of the road surface. Centerline rumble strips are explained below.

In Nebraska, it is a statewide highway safety project, funded by Federal Highway Safety Improvement Funds. The Federal-aid funding program (SAFETEA-LU) has as its goal to achieve a significant reduction in traffic fatalities and serious injuries on all public roads. This goal is a reduction in the number of crossover accidents.

Construction of the rumble strips is consistent with Nebraska standards.

- 12” pattern of 7” rumble and a 5” gap.

- Set ½” Deep.

The rumble strips are intended to wake up dozing drivers who are in danger of crossing the centerline and are vulnerable to high severity head-on collisions. Sites that historically had a high number of cross-centerline crashes were selected for rumble strip installation. Test projects by the Nebraska Department of Transportation (NDOT) on selected roadways showed centerline crossover accidents were reduced after centerline rumble strips were installed.

- Hwy 34 – Lincoln to Seward, and Hwy 77/92 – Wahoo to Yutan.

- The total cross-centerline accident rate decreased by 64.0%.

- An 89.6% decline in property-damage-only accidents.

- A 44.4% decrease in fatal and injury crashes.

- An added benefit for the centerline rumble strips is that the painted stripe generally ends up over the top of the strips. This tends to increase its visibility, especially on wet roadways

The current project is the installation of centerline rumble strips along 208 miles of state highways. If Federal funds are available in the future, more centerline rumble strips may be considered on additional highways.

The Nebraska Department of Transportation (NDOT) Traffic Analysis Unit uses BOTH people and automation to collect traffic information. That info is developed into classification data used by planners, engineers, and designers. Traffic forecasts can be developed from it, and the data helps cities and other public agencies when they do their planning.

Automated Traffic Counts, done with a portable machine can be done at thousands of locations each year, at any time of the day or week, and are the least expensive on a per count basis. However, they are somewhat limited as to what they can count. Most count only volume, with only some able to give info on the classification of traffic by vehicle type.

Manual Classification Counts are done at approximately 150 locations around the state per year. They usually occur on weekdays, and are usually at intersections, to provide greater vehicle info. Counts are taken for 8 hour periods and the sample counts are adjusted to represent 24 hour annual average volumes. However, an advantage of the Manual Count is that the operator can also see what types of vehicles are counted...motorcycles, passenger cars, school & city busses, trucks and other types of multi-axle vehicles. In all, vehicles are classified into one of 14 different vehicle categories, so even though the time frame for the manual count is limited when compared to Automated Counts, more precise classification info can be gathered.

Contrast Pavement Markings Information

Purpose...Highway Markings provide guidance and information for the motorist. Major types of highway markings include pavement and curb markings, object markers, delineators, colored pavement, and barricades. In some cases markings are used to supplement other traffic control devices such as signs and signals. Some of the more common highway markings include:

- solid white line - the outer driving edge of a roadway.

- dashed white line - traffic lanes for motorists going in the same direction.

- dashed yellow center line - separates opposing traffic on the same roadway.

- solid yellow line - indicates no passing zones on two lane highways.

Miles & Miles...There are 9,959 miles of highways on Nebraska's state highway system, however, a number of roads on the state system, such as the Interstate, have several lanes. This means that NDOR has approximately 22,634 lane miles of highway to stripe.

Durability...Highway markings may last from several months to several years, depending on the amount of traffic. NDOR has 6 crews, state wide, that re-stripe the various highways on a regular schedule. The schedules vary with the areas and the highways. Interstate 80, in the Omaha area is re-striped three times a year or as needed. Highways, in other areas, are re-striped every other year, or as needed.

Materials Used...The Department is using preformed tape markings and plowable pavement markings on certain areas of Interstate 80. The majority of traffic paint applied by state crews is water-based traffic paint, along with a small amount of solvent-based traffic paint used in the Omaha area.

We use an average of 300,750 gallons of white paint and 145,000 gallons of yellow paint each year re-striping highways. We also use small glass beads which are applied directly onto the surface of the wet paint for added visibility. NDOR applies approximately 1,692,000 pounds of beads each year, not including beads used in highway striping that is contracted out each year. Numerous quality control tests are performed on each type of paint used, as well as on the glass beads which are added to the paint. These tests are to determine both the durability and reflectivity of both the paint and the glass beads.

This is called dowel bar retrofitting.

Background: As vehicles travel down the highway, the weight of the vehicle load passes from one concrete panel to the next. In older highways, dowel bars (steel rods) were placed at transverse joints along the road to help transfer the weight of vehicles from one panel to the next. Since many of the early dowel bars corroded and needed to be replaced, their use was discontinued. However, without the dowel bars, weight load transfer was dependent on the strength and cohesion of the concrete at the joint, and the support of the road bed. Over time this joint can break down and fail to provide a good load transfer. When this happens the joint begins to displace, or fault, and provides the “thump-thump” sound you may hear while driving.

We would then have to grind the pavement to again provide a smooth ride. This would last approximately 6-8 years and then the “faulting” would return. Faulting can also have undesirable effects. Also, joint seals tend to open up and allow moisture to enter. Moisture damages and weakens the sub grade, allowing the loss of sub grade material that causes edge cracking, pot holes, and settling or cracking of the adjacent shoulder.

Solution: NDOR began using epoxy coated dowel bars about four years ago to alleviate this problem. The epoxy coating retards the effects of moisture and chemicals on the steel bar. The dowel bars are installed by cutting slots into the existing pavement, three in each wheel path, a dowel bar is placed in each slot, and the slot is filled with high strength non shrink grout. The area is then ground smooth and the joint is resealed. The retrofit also prolongs the life of any resurfacing that might have to be done at a later date. NDOR has completed about a dozen retrofit projects over the last four years and plans to do three to four retrofit projects each year in coming years.

New Construction: Epoxy dowel bars are now used in new construction. They are put in place prior to paving and are not visible once the paving is complete. The installation of dowel bars extends the life of the pavement, improves the ride quality and is less expensive than the maintenance activities that would be required without them.

In December 2009, after extensive testing, the Federal Highway Administration authorized use of flashing yellow arrows nationwide. A study conducted by the National Cooperative Highway Research Program determined that drivers had fewer crashes with flashing yellow left-turn arrows than with traditional yield-on-green signal configurations.

Flashing yellow arrow traffic signals feature a flashing yellow arrow in addition to the standard red, yellow and green arrows. When illuminated, the flashing yellow arrow allows waiting motorists to make a left-hand turn after yielding to oncoming traffic. Otherwise, the new traffic signals work the same as traditional signals.

What the Arrows Mean

Solid red left-turn arrow – Drivers intending to turn left must stop and wait. Do not enter an intersection to turn when a solid red arrow is being displayed.

Solid yellow left-turn arrow – The left-turn signal is about to change to red and drivers should prepare to stop or prepare to complete a left turn if they are legally within the intersection and there is no conflicting traffic present.

Flashing yellow left-turn arrow – Drivers are allowed to turn left after yielding to all oncoming traffic and to any pedestrians in the crosswalk. Oncoming traffic has a green light. Drivers must wait for a safe gap in oncoming traffic before turning.

Solid green left-turn arrow – Left turns have the right-of-way. Oncoming traffic has a red light.

To learn more about Alkali-Silica Reaction (ASR), download this PDF.

Share the Road

A tractor operator’s best defense to avoid a collision with a motor vehicle on public roads is to make the tractor as visible as possible. This is critical because of the difference in travel speed. For example, a car traveling 65 miles per hour approaches a tractor traveling 20 miles per hour in the same direction on the road. If the driver of the car first notices the tractor while still 400 feet behind it, the driver has less than 7 seconds to avoid a collision with the tractor.

Nebraska traffic law requires that farm tractors with a maximum speed of 25 miles per hour be equipped with a slow-moving-vehicle (SMV) emblem on the rear of the tractor. When towing a trailer or other equipment that blocks the SMV emblem, another SMV emblem must be attached at the rear of the towed equipment.

Standards for shape, color, and placement of the SMV emblem established by the American Society of Agricultural Engineers, the American National Standard Institute, and the Society of Automotive Engineers have been adopted into law. The emblem shall be an equilateral triangle at least 13.8 inches high (plus or minus 0.3 inches), and must be a fluorescent, red-orange material with a border of red retro-reflective material. The fluorescent material is visible in daylight and the reflective border shines when illuminated by headlights at night.

The SMV emblem must be mounted at the rear, and as close to the center of the tractor or equipment as possible. It must be mounted with the point up; the lower edge of the emblem must be at least 2 feet, but not more than 6 feet above the ground.

Highway Driving

If the tractor is equipped with a roll over protection structure (or ROPS), make sure to securely fasten the seat belt. This will keep you within the zone of protection in case the tractor overturns. Remember to turn on headlights and flashers to warn other drivers of your presence. When driving on the highway, stay as far to the right as possible, but avoid driving on uneven road surfaces at high speeds (i.e., driving with the left wheels on smooth pavement and right wheels on rough, loose shoulders). This could result in erratic steering, uneven braking, loss of control, and tractor overturns. If it is necessary to let cars pass you, slow down, pull to a secure shoulder, stop, and let them pass.

If possible, avoid left turns. Most tractor-motor vehicle collisions occur when the motorist assumes the tractor is pulling to the right, the motorist makes the move to drive around the tractor, and instead the tractor makes a wide left turn.

What & Why: Most motorists have, at one time or another, driven on a milled road. Milling is the process of removing high spots, bumps and ruts from the road’s surface for a more even surface, and is done for the safety of the driving public. It can be done as a stand alone project or in connection with a resurfacing project. Milling promotes proper drainage to prevent standing water and/or ice from building up on the road which can cause hydroplaning or loss of directional control.

Personnel: The Department of Transportation has a four member crew that specializes in fine profile milling for state maintenance projects, and if needed, they can be any place in the State within 48 hours. The crew coordinates with each of NDOT’s eight districts to determine what milling projects are needed, and a schedule is arranged. The milling crew works on shorter maintenance projects. Longer projects and milling connected with resurfacing projects are frequently done by contractors. While in each district, the milling crew works with the maintenance crew from each supervisor’s area. The maintenance crew provides the traffic control, water trucks, broom operator and trucks to haul the millings to stockpile sites. The millings are used to build up shoulders, fill washout and occasionally for blade patching if the material is good enough. Some also may be used in the yards or on gravel/dirt roads for sub-grade material.

Facts & Figures: The State’s current milling machine is approximately 6 years old. It has a 7’ 2” drum with approximately 453 carbide bits. The bits will last from ½ day to several days depending on the type of surface being cut. The machine can cut anywhere from 1/4” to 10” deep with most projects being cut ½ to ¾ inch. The cutting is followed by an armor coat to reseal the road surface. On average the crew will mill 1 ¾ million to 2 million square yards a year.

Motorists on Nebraska's state highways may see windsocks at various locations. The windsocks were put up to indicate wind strength and direction for truckers and other people driving high profile vehicles.

There are currently 16 windsocks on Nebraska's highways...12 at various locations along Interstate 80, 1 on US Highway 77, south of Lincoln, 1 on Highway 20 in central Nebraska, and 2 on Highway 71, north of Scottsbluff.

The windsocks have been up since 2002, and we have received favorable comments from the trucking community on their usefulness.